Service & Support

Great systems are only as good as great support, and a cornerstone of our business is providing a 'beginning-to-end' solution.

H2flow services numerous key industries globally. Ensuring our customers are 100% satisfied with our products is our number one priority. Our mission is to enable our customers to achieve their goals by providing them with premium products and unparalleled support.

With almost 20 years of experience providing customers with motor control solutions, we have a profound understanding of what it takes to optimize our customer’s processes. We have the knowledge to assist you with everything from product installation, to setup, to troubleshooting – freeing you to focus on your core business.

Telephone Support

At H2flow, our unwavering devotion to developing first-class products is only surpassed by our dedication to customer satisfaction. We strive to ensure that our customers receive only the very best products and services. If you’d like to speak to an H2flow representative about one of our products, please contact us.

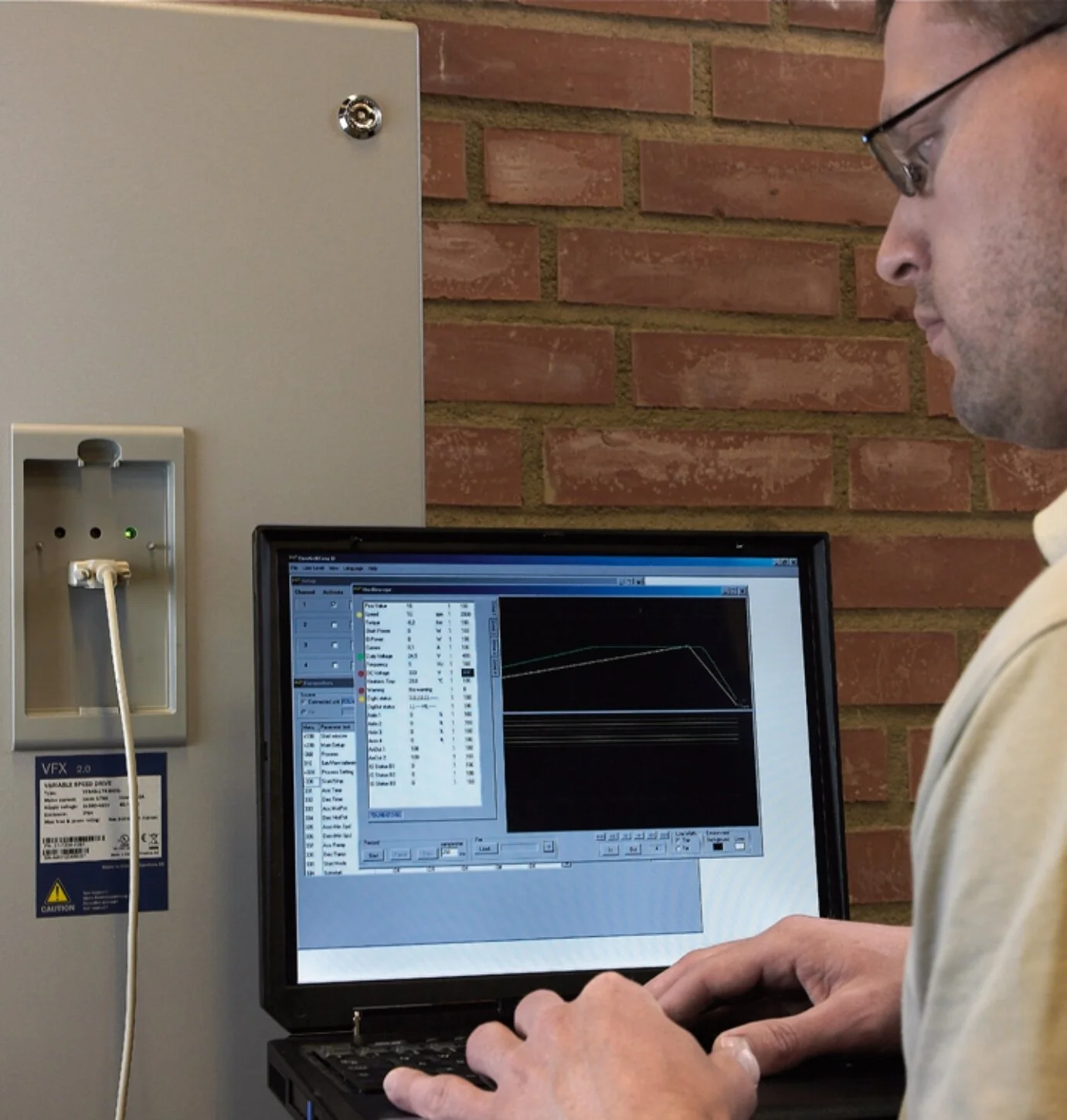

Commissioning & Training

Great systems are only as good as great support, and a cornerstone of our business is providing a ‘beginning-to-end’ solution.

Although many of our systems are so intuitive that they don’t require on-site commissioning, some of our more complex engineered solutions will benefit from this service. In the event that system commissioning is provided, our standard warranty is automatically increased from 1-year to 3-years.

At the conclusion of system commissioning, one of our engineers will provide product training to customer designated staff.

Options add functionality

Select Emotron products allow for options that add functionality the ability to fully utilize the product according to your needs.

Communication options for certain Variable Frequency Drives and Soft Starts include Fieldbus communication via Profibus and DeviceNet, Industrial Ethernet communication via Modbus/TCP, EtherCAT and Profinet, and serial communication via RS232 or RS485 with Modbus RTU.

Pre-engineering

Our control panel services include the following fundamental steps in order to ensure that the end product performs exactly as intended:

Pre-sale customer review of the precise needs of the application

Design engineering evaluation between our sales and engineering departments

Production of Engineering Drawings for customer review and comment

Only by following this rigid procedure can our customer be sure that their control panel’s functionality, quality, and performance is exactly as was intended.